Chain Grades Chart

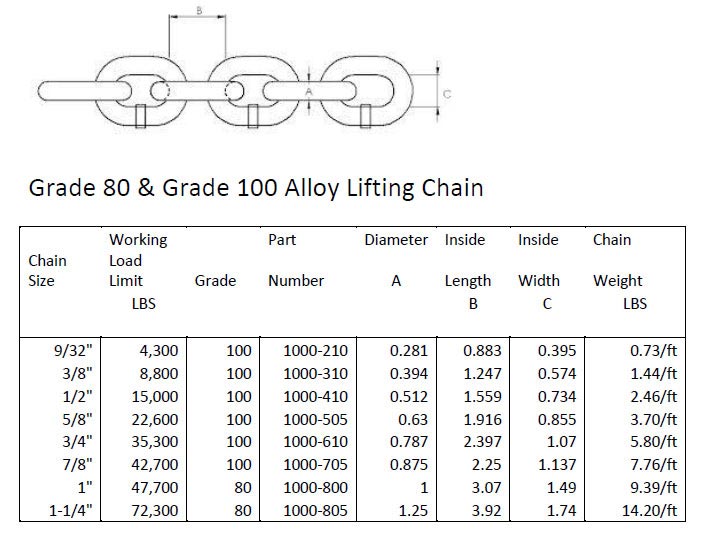

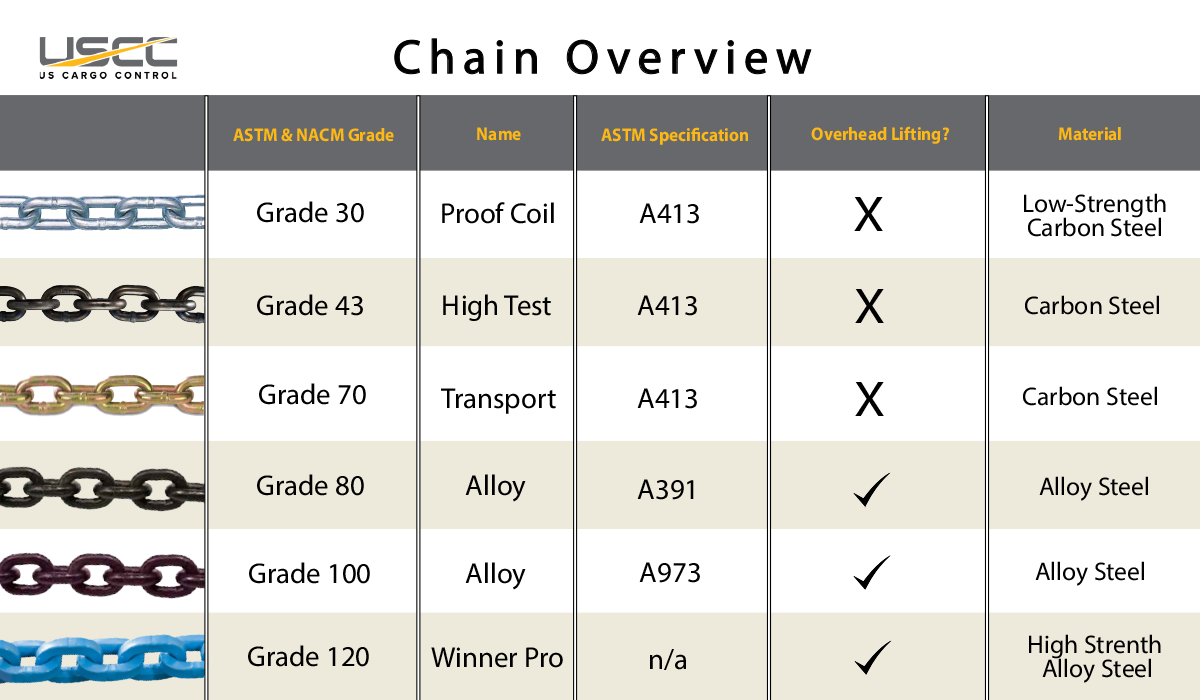

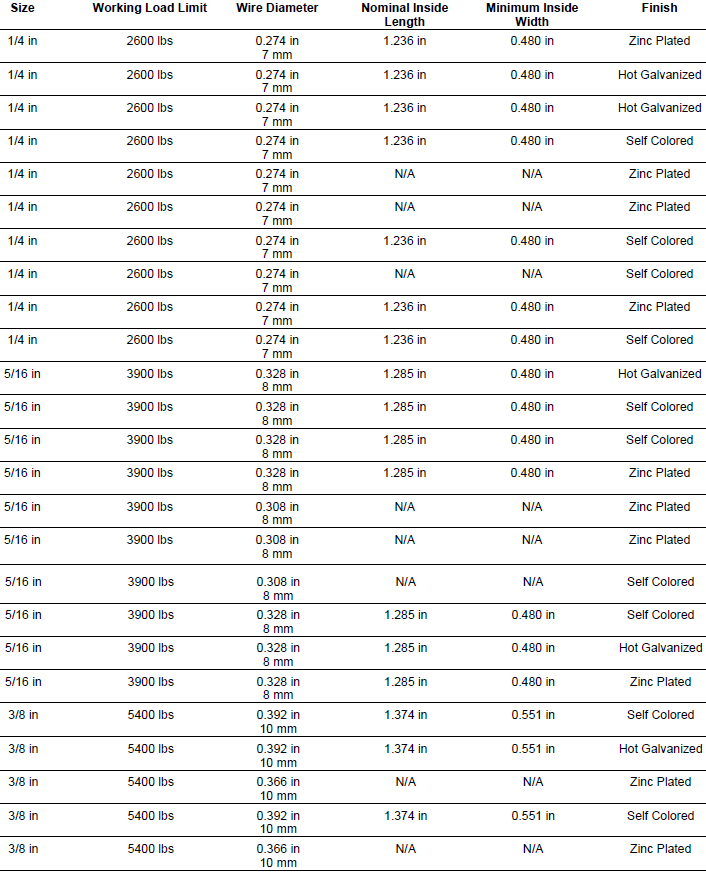

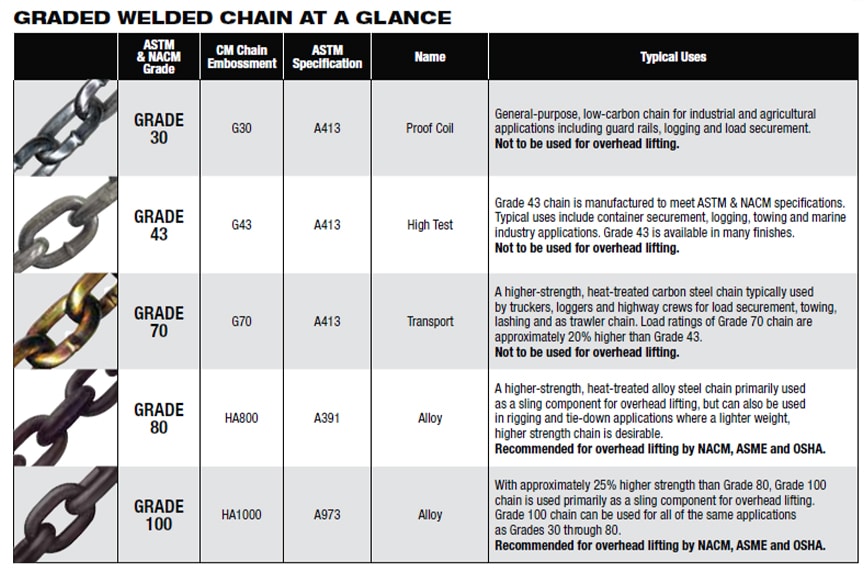

Chain Grades Chart - Web the welded steel chain specification pertains to the following chain grades: Chain grades are a standard method for showing the ultimate breaking strength (tensile strength) of a chain. Chain grades are determined by calculating newtons per square millimeter, using the formula “n/mm2”. Unraveling the alphanumeric codes that signify chain grades. Web while there is a massive variety of chain grades on the market and important differences in chain strengths, materials, and uses, we hope that this article will help. The common chain grades used today are g30, g43, g70, g80, g100, and. Grades help determine what sort of applications are appropriate for a given chain. Understanding these grades is crucial for selecting. Web see chain load ratings and chain weight ratings for all types of chains! When selecting anchor or windlass chain, there. Whether it’s for overhead lifting, towing, or securing loads,. Web in this article, we unravel the intricacies of identifying chain grade, shedding light on the key factors, markings, and insights that empower industries to distinguish. Web understanding the differences in chain grades is vital for selecting the right chain for specific applications. Alloy chain grade 80 or grade 100 should be used for overhead lifting. Web the different chain grades explained, with their permitted uses and free charts/cheats to download and print. Common grades include grade 30, grade 43, grade 70, grade 80, and. Web chains come in various grades, each denoting specific characteristics and applications. Web while there is a massive variety of chain grades on the market and important differences in chain strengths, materials, and uses, we hope that this article will help. The common chain grades used today are g30, g43, g70, g80, g100, and. Unraveling the alphanumeric codes that signify chain grades. Web chains come in various grades, each denoting specific characteristics and applications. Web chain grades describe the ultimate breaking strength or tensile strength of a given type of chain. The common chain grades used today are g30, g43, g70, g80, g100, and. Chain grades and links explained. Astm states that alloy chain shall be. Unraveling the alphanumeric codes that signify chain grades. Web which chain grade should be used for which type of application? Web the different chain grades explained, with their permitted uses and free charts/cheats to download and print. Common grades include grade 30, grade 43, grade 70, grade 80, and. Web understanding the differences in chain grades is vital for selecting. Chain grades and links explained. Astm states that alloy chain shall be. Web the welded steel chain specification pertains to the following chain grades: Whether it’s for overhead lifting, towing, or securing loads,. Web first, all of laclede’s domestic chain is stamped about every six links to help you identify the grade of chain. Just look for the “l” and then the number after it. Web the welded steel chain specification pertains to the following chain grades: Common grades include grade 30, grade 43, grade 70, grade 80, and. Web understanding the differences in chain grades is vital for selecting the right chain for specific applications. Web alloy chain grade 80 or grade 100. Chain grades are a standard method for showing the ultimate breaking strength (tensile strength) of a chain. When selecting anchor or windlass chain, there. Web the different chain grades explained, with their permitted uses and free charts/cheats to download and print. Web this guide will delve into the nuances of chain grades, the types available, and their respective working load. Grade 100 alloy chain, grade 80 allow chain, grade 70 transport chain, grade 43 high test chain, grade. Our chain ratings guide shows all about chain weight/load ratings. Chain grades are determined by calculating newtons per square millimeter, using the formula “n/mm2”. Web the different chain grades explained, with their permitted uses and free charts/cheats to download and print. Common. Whether it’s for overhead lifting, towing, or securing loads,. Web here, we’ll look at four chain grades and explore how they differ. Web see chain load ratings and chain weight ratings for all types of chains! Alloy chain grade 80 or grade 100 should be used for overhead lifting. Web alloy chain grade 80 or grade 100 should be used. Web first, all of laclede’s domestic chain is stamped about every six links to help you identify the grade of chain. Grades help determine what sort of applications are appropriate for a given chain. Web the grade of a chain is determined by factors such as material composition, tensile strength, and heat treatment. Web this guide will delve into the. Chain grades are determined by calculating newtons per square millimeter, using the formula “n/mm2”. Web the welded steel chain specification pertains to the following chain grades: Web here, we’ll look at four chain grades and explore how they differ. Unraveling the alphanumeric codes that signify chain grades. Astm states that alloy chain shall be able to elongate a minimum of. Unraveling the alphanumeric codes that signify chain grades. Web while there is a massive variety of chain grades on the market and important differences in chain strengths, materials, and uses, we hope that this article will help. Web the grade of a chain is determined by factors such as material composition, tensile strength, and heat treatment. Web the welded steel. Our chain ratings guide shows all about chain weight/load ratings. Understanding the correlation between grades and chain strength. Web the different chain grades explained, with their permitted uses and free charts/cheats to download and print. The common chain grades used today are g30, g43, g70, g80, g100, and. Common grades include grade 30, grade 43, grade 70, grade 80, and. Web in this article, we unravel the intricacies of identifying chain grade, shedding light on the key factors, markings, and insights that empower industries to distinguish. Web understanding the differences in chain grades is vital for selecting the right chain for specific applications. Grade 100 alloy chain, grade 80 allow chain, grade 70 transport chain, grade 43 high test chain, grade. Web see chain load ratings and chain weight ratings for all types of chains! Web which chain grade should be used for which type of application? Alloy chain grade 80 or grade 100 should be used for overhead lifting. Web while there is a massive variety of chain grades on the market and important differences in chain strengths, materials, and uses, we hope that this article will help. Web chains come in various grades, each denoting specific characteristics and applications. Astm states that alloy chain shall be able to elongate a minimum of 20% before fracture (7.3.5). Unraveling the alphanumeric codes that signify chain grades. Chain grades are a standard method for showing the ultimate breaking strength (tensile strength) of a chain.Chain Grades Chart Cargo Chain Strength and Grades Guide for Flatbedder’s

Chain Grade Rating Chart Ponasa

Chain Grades Chart Cargo Chain Strength and Grades Guide for Flatbedder’s

Chain Grades Chart Cargo Chain Strength and Grades Guide for Flatbedder’s

Comparing Chain Grades U.S. Cargo Control US Cargo Control

Chain Grades And Strengths Chart

Chain Grade Chart A Visual Reference of Charts Chart Master

What Are the Different Grades of Chain?

What Are the Different Grades of Chain?

Chain Grades Chart Cargo Chain Strength and Grades Guide for Flatbedder’s

Web This Guide Will Delve Into The Various Chain Grades Used In The Rigging Industry, Their Common Applications, Differences, Potential Problems, And Common.

Web The Grade Of A Chain Is Determined By Factors Such As Material Composition, Tensile Strength, And Heat Treatment.

Whether It’s For Overhead Lifting, Towing, Or Securing Loads,.

Chain Grades And Links Explained.

Related Post: