Machined Finish Chart

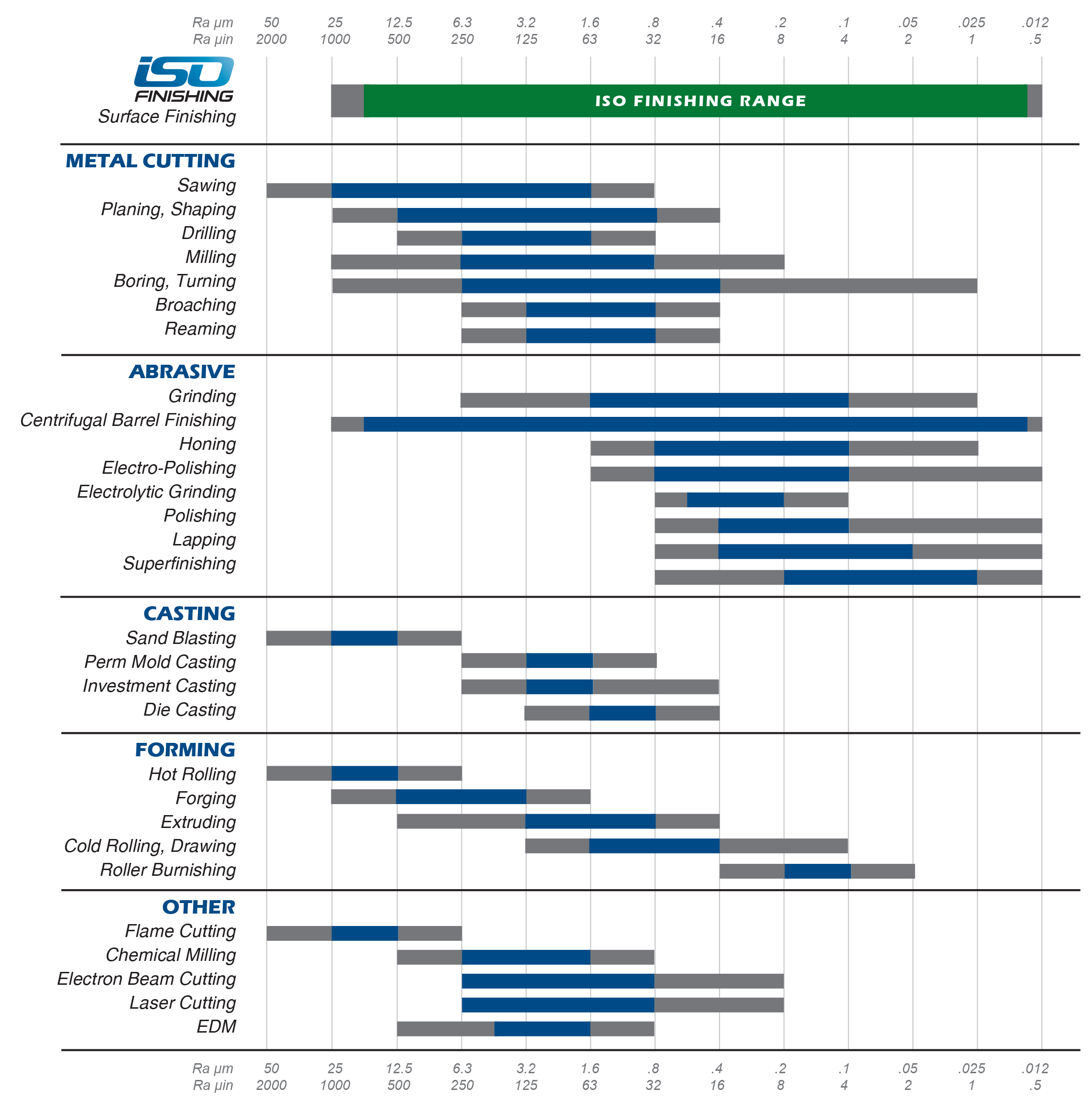

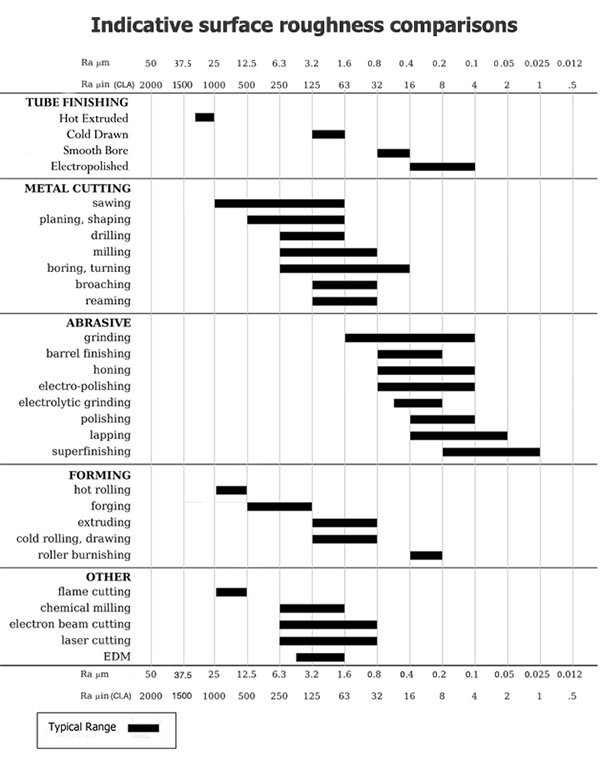

Machined Finish Chart - Web introducing the machining surface finish chart, conversion, comparator photos, method, finish degree, ra, rz, rms for iron and steel castings by dandong foundry in china. Web a surface finish chart such as this could include the following parameters: It depends on the structure of the metal before and after machining, depends on cutting conditions such as type and degree of sharpness of the cutting tool, depth of cut, amount of feed, coolant used, working conditions such as. Manufacturers always use it as a reference material to ensure quality in the manufacturing process. There are wide ranging variations in finishing and edge conditions. Web the following charts and tables convert surface finish or roughness between selected industry standard units. By looking at these charts we can choose material and process wisely for getting the desired surface roughness. Web the machining surface finish chart offers important guidelines for measuring standard surface finish parameters. See how iso finishing compares to common metal manufacturing practices. Here’s a chart table showing the relative surface finish roughness of various manufacturing processes: Web here’s a table with a chart demonstrating the relative surface roughness of several production processes: Rt = roughness, total in microns. Web the surface roughness chart is a tool used by engineers and manufacturers to understand the various levels of surface finish in machining and manufacturing processes. Web surface finish charts help to understand materials’ surface parameters effectively, be it smooth or rough surfaces. This will help designers and manufacturers select surface finishing techniques that are most effective for products. See how iso finishing compares to common metal manufacturing practices. Surface finish, when it is intended to include all three characteristics, is often called surface texture to avoid confusion, since machinists often refer to surface roughness as surface finish. This is a calculation of the average length between all the peaks and valleys (or the average height) from the mean line of the surface. Web by better understanding the different machined surface finishes, the varying roughness levels and how surface finishes impact function, you can ensure the quality and performance of manufactured applications. By looking at these charts we can choose material and process wisely for getting the desired surface roughness. Web for example, a machined surface may need to transition to a ground surface to meet the surface finish requirement. Web you can use a surface finish chart to see which one is suited for your specific application. Web ra surface finish chart | surface roughness chart. The best surface chart should have more columns so that you can compare. Manufacturers consistently reference it to guarantee product quality during the manufacturing process. Web additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for manufacturing processes. This can be used to help determine the best machining process for a given surface. Web you can use a surface finish chart to see which one is suited for. Web a surface finish chart such as this could include the following parameters: Web the machining surface finish chart provides important instructions for gauging standard surface finish characteristics. Web testing and quality control. Web additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for manufacturing processes. This step is essential for identifying any defects or. Web here’s a table with a chart demonstrating the relative surface roughness of several production processes: Web ra surface finish chart | surface roughness chart. It depends on the structure of the metal before and after machining, depends on cutting conditions such as type and degree of sharpness of the cutting tool, depth of cut, amount of feed, coolant used,. Web additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for manufacturing processes. Web surface finish is a measure of the overall texture of a surface that is characterized by the lay, surface roughness, and waviness of the surface. This step is essential for identifying any defects or deviations from the specified finish grade. Surface. Web the surface roughness chart is a tool used by engineers and manufacturers to understand the various levels of surface finish in machining and manufacturing processes. This can be used to help determine the best machining process for a given surface. Web surface finish specification and comparison. Check how injection moulding surface finish can be defined and used as a. Manufacturers always use it as a reference material to ensure quality in the manufacturing process. The most commonly used parameter is roughness average (ra). Web testing and quality control. The most common type is the roughness chart which shows a graphical representation of the roughness of a surface. Rt = roughness, total in microns. Web the machining surface finish chart provides important instructions for gauging standard surface finish characteristics. The most common type is the roughness chart which shows a graphical representation of the roughness of a surface. Rt = roughness, total in microns. See how iso finishing compares to common metal manufacturing practices. Web by better understanding the different machined surface finishes, the. Web for example, a machined surface may need to transition to a ground surface to meet the surface finish requirement. The most common type is the roughness chart which shows a graphical representation of the roughness of a surface. Web the finish on a metal surface after machining depends mainly on the material and some are as follows. This can. Then, you can use the chart to determine if your surface meets any necessary standards or if you need to adjust it. The table below converts surface finish or roughness between ra, rz, and rms indicators. Web the following charts and tables convert surface finish or roughness between selected industry standard units. After the finishing process is complete, it's vital. This step is essential for identifying any defects or deviations from the specified finish grade. The most commonly used parameter is roughness average (ra). Web the machining surface finish chart provides important instructions for gauging standard surface finish characteristics. Web a typical cnc machining finish, ‘as machined’, is smooth to the touch (ra3.2) but will contain visible machining lines from the cutting tool. Understanding surface finish is crucial in engineering, manufacturing, and design. Web surface finish specification and comparison. Web the finish on a metal surface after machining depends mainly on the material and some are as follows. Trump grabbed his ear and took a step backward before ducking to the ground. Web by better understanding the different machined surface finishes, the varying roughness levels and how surface finishes impact function, you can ensure the quality and performance of manufactured applications. This level of roughness is suitable for most parts; Web you can use a surface finish chart to see which one is suited for your specific application. Web the machining surface finish chart offers important guidelines for measuring standard surface finish parameters. The sounds of several rounds of gunfire rang out across the rally site. In this guide, we dive deep into surface finish symbols, charts, and measurements such as ra and rz. Web the following charts and tables convert surface finish or roughness between selected industry standard units. Listed are some of the more common manufacturing techniques and their corresponding ra surface finish values.Surface Roughness Chart Comparison ISO Finishing

Machining surface finish chart, conversion, comparator, method, degree

Surface Finish Machinng Chart PDF PDF Surface Roughness Machining

Machining Surface Finish Chart Comparator Method Degr vrogue.co

Complete Surface Finish Chart, Symbols & Roughness Conversion Tables

Surface Finish Machinng Chart Pdf Surface Roughness Machining IMAGESEE

Standard Machining Surface Finish

Machining Surface Finish Symbols Chart

Machining Surface Finish Chart

Selecting right surface roughness for CNC machining Xometry Europe

Surface Finish Directly Impacts Functionality, Performance, And Longevity.

Web Trump Didn’t Finish His Sentence.

Manufacturers Consistently Reference It To Guarantee Product Quality During The Manufacturing Process.

The Table Below Converts Surface Finish Or Roughness Between Ra, Rz, And Rms Indicators.

Related Post: