Plastic Melting Temperature Chart

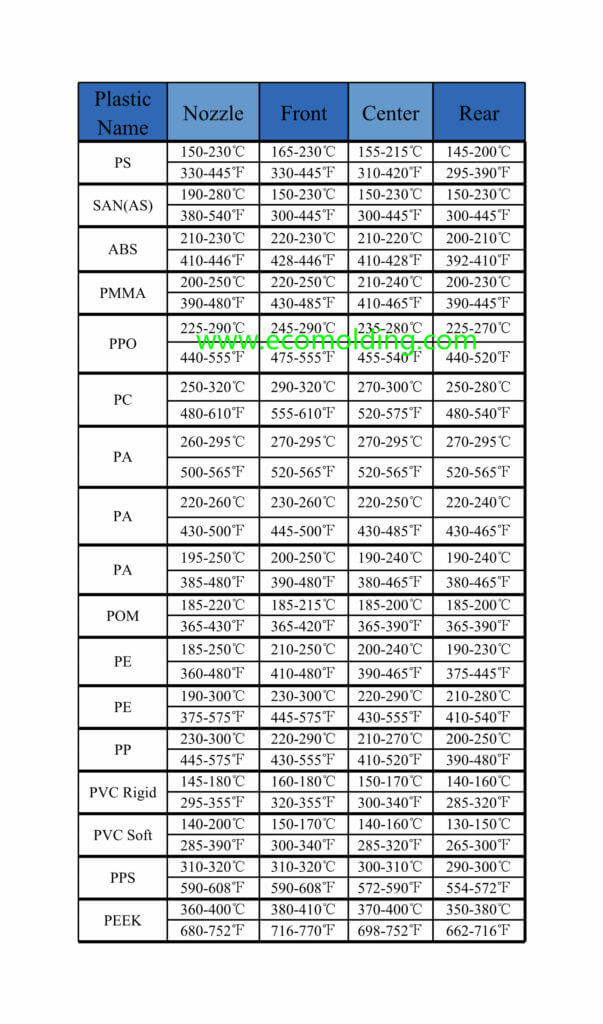

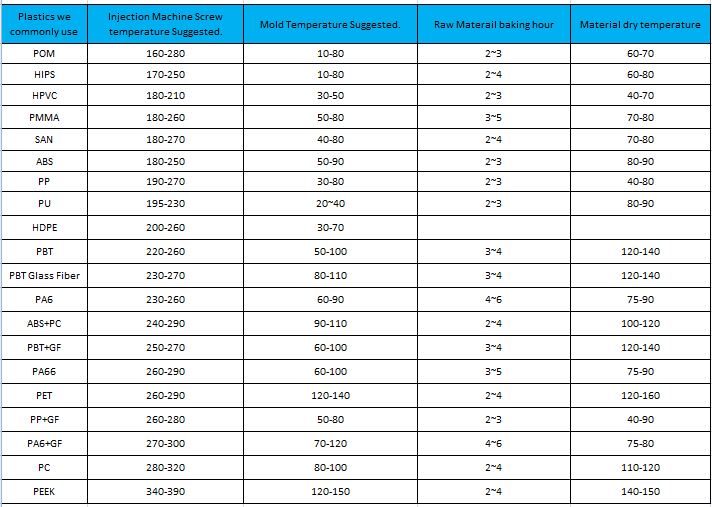

Plastic Melting Temperature Chart - The melting point of ldpe is 105 degrees celsius, while that of hdpe is 125 degrees celsius. Don't miss out on quality and efficiency—read now! Web below is a list of the most common considerations. Manufacturers often incorporate additives into thermoplastics, such as pigments, plasticizers, or stabilizers, to modify the material's properties, including its melting point. Web the chart should help you know the melting point of the plastics for quick and safe disposal of them without inconsequence. (1 atm = 101,325 pa) click on the icon to switch between degrees celsius (°c) and degrees fahrenheit (°f) units. The intricacies of mold temperature in the injection molding process are pivotal to achieving precision and quality in the final product. Web at temperatures between 392 and 536 degrees fahrenheit and 200 and 280 degrees celsius, various types of polypropylene melt. The exact temperature thresholds and performance will vary for each different plastic material. This temperature will gradually melt the plastic. The intricacies of mold temperature in the injection molding process are pivotal to achieving precision and quality in the final product. The melting point of a plastic is fundamentally influenced by its chemical composition. Take abs as an example, which melts at around 200°c (392°f). Web a detailed description of plastic melting and molding temperature ranges, inclusive of the recommended temperature values for all plastics. Web the chart should help you know the melting point of the plastics for quick and safe disposal of them without inconsequence. Web what is the melting point of plastics. In addition, factors like part geometry and material thickness will also affect material properties under extreme temperatures both high and low. Pvc begins to melt in the 160 to 210 degrees celsius (320 to 410 degrees fahrenheit). Web knowing the optimal plastic material melt & mould temperatures is essential for all manufacturers. Manufacturers often incorporate additives into thermoplastics, such as pigments, plasticizers, or stabilizers, to modify the material's properties, including its melting point. Web a thorough grasp of the temperature ranges and variables affecting plastic melting points allows producers to improve product quality, optimize production parameters, and open up new avenues for innovation. The melting point of a plastic is fundamentally influenced by its chemical composition. The exact temperature thresholds and performance will vary for each different plastic material. Ask an expert or. The melting point of a plastic is fundamentally influenced by its chemical composition. Web see below for our chart on plastic processing and drying temperatures, along with plastic and abs molding temperatures. Preheat the oven to around 300 °f (149 °c). Web below is a list of the most common considerations. Don't miss out on quality and efficiency—read now! Manufacturers often incorporate additives into thermoplastics, such as pigments, plasticizers, or stabilizers, to modify the material's properties, including its melting point. Web pla's melting point typically ranges between 150°c and 180°c, although this varies depending on the specific grade of pla and whether the material has any additives. Ask an expert or get a quote. Web a thorough grasp of. Take abs as an example, which melts at around 200°c (392°f). Explorers dreamed for centuries of discovering a northwest passage through the arctic. (1 atm = 101,325 pa) click on the icon to switch between degrees celsius (°c) and degrees fahrenheit (°f) units. It won’t take a blasting hot oven to melt most common plastics, such as polypropylene, and you. The melting point of ldpe is 105 degrees celsius, while that of hdpe is 125 degrees celsius. Web what is the melt temperature? The answer to that question certainly would be helpful for processing and troubleshooting. We’ve also highlighted why it’s important to recycle plastic. Pvc begins to melt in the 160 to 210 degrees celsius (320 to 410 degrees. 7 cobham drive orchard park, ny 14127. Web knowing the optimal plastic material melt & mould temperatures is essential for all manufacturers. The melting point of a plastic is fundamentally influenced by its chemical composition. Use our plastics properties table to sort and compare plastic materials. Web unlock the secrets of optimal plastic melt and mould temperatures. This critical characteristic determines the conditions under which plastic can be shaped, recycled, and utilized in various applications. The melting point of a plastic is fundamentally influenced by its chemical composition. Find out what temperatures you should be using for your plastic material. The melting point of ldpe is 105 degrees celsius, while that of hdpe is 125 degrees celsius.. Explorers dreamed for centuries of discovering a northwest passage through the arctic. Please contact plastic service centers if you have any questions about processing and drying temperatures for plastic resins. 7 cobham drive orchard park, ny 14127. Web at temperatures between 392 and 536 degrees fahrenheit and 200 and 280 degrees celsius, various types of polypropylene melt. The exact temperature. Web as an engineer in the plastics industry, understanding the plastics melting temperature, injection molding temperature, drying temperature and drying time of raw materials will help a lot in improving production efficiency, product quality and higher resource utilization. Find out what temperatures you should be using for your plastic material. Pvc begins to melt in the 160 to 210 degrees. Use our plastics properties table to sort and compare plastic materials. Web unlock the secrets of optimal plastic melt and mould temperatures. Web a thorough grasp of the temperature ranges and variables affecting plastic melting points allows producers to improve product quality, optimize production parameters, and open up new avenues for innovation. Pvc begins to melt in the 160 to. It won’t take a blasting hot oven to melt most common plastics, such as polypropylene, and you don't want it to be so hot that the plastic burns. Web the melting point of plastic refers to the temperature at which it transitions from a solid to a liquid state. Web see below for our chart on plastic processing and drying temperatures, along with plastic and abs molding temperatures. Find out what temperatures you should be using for your plastic material. Review typical, physical, thermal, optical, electrical properties. Web a detailed description of plastic melting and molding temperature ranges, inclusive of the recommended temperature values for all plastics. Manufacturers often incorporate additives into thermoplastics, such as pigments, plasticizers, or stabilizers, to modify the material's properties, including its melting point. Web unlock the secrets of optimal plastic melt and mould temperatures. Web at temperatures between 392 and 536 degrees fahrenheit and 200 and 280 degrees celsius, various types of polypropylene melt. Web the chart should help you know the melting point of the plastics for quick and safe disposal of them without inconsequence. Web knowing the optimal plastic material melt & mould temperatures is essential for all manufacturers. Web what is the melt temperature? Web plastic melting temperature and injection molding temperature chart. Perfect for injection moulding projects. The melting point of plastic decreases if it is impure because of the presence of other compounds. The intricacies of mold temperature in the injection molding process are pivotal to achieving precision and quality in the final product.درجات الانصهار للبلاستيكMelting temperatures of polymers YouTube

Melting temperatures of plastics. Download Scientific Diagram

Plastic Melting Temperature Chart

What is the best injection molding

Plastic Melting Temperature Chart

Mastering Plastic Material Melt & Mould Temperatures Essential Tips

Material & Mold Temperature information in injection molding

Plastic Melting Point Chart

Temperature Considerations in Plastic Thermoforming Material Selection

Plastic Melting Point Chart

Web The Following Table Provides A Comprehensive List Of Melting Point Values For Different Polymers And Plastics At 1 Atmospheric (Atm) Pressure.

Web Glass Transition Temperature Tg And High Elastic Rubbery State A Significant Physical Change Occurs When Plastics Are Heated To The Glass Transition Temperature Tg Marks The Start Of The Transition From A Hard And Brittle State To A Soft State With The Exact Temperature Depending On The Type Of Plastic And Its Molecular Structure For Example.

Don't Miss Out On Quality And Efficiency—Read Now!

Take Abs As An Example, Which Melts At Around 200°C (392°F).

Related Post: